As experts in specialty coffees for nearly 25 years, La Colombe® Coffee Roasters has been making people happy one farm, one bean, one cup, and one home at a time. That’s why we knew we had to partner with them to bring the great taste of their specialty La Colombe Corsica and Monaco coffees to the office!

To celebrate our partnership, we sent a few lucky folks to one of La Colombe’s favorite coffee farms in Costa Rica. Rebecca Williams, Senior Coffee Development Technologist here at Lavazza Professional, shared her experience of visiting origin.

Tell us a bit about what you learned about coffee harvesting while in Costa Rica.

The most impactful to me was watching the producers pull up to the coffee mill with anywhere from one bag of coffee cherries to a truck of loose coffee cherries. Coffee must be processed or spread onto drying patios as soon as the cherries are picked, otherwise it will begin to ferment or go moldy. Whether you have a few trees on your property or a large farm, the cherries are picked and brought to the mill every day during the harvest season. The mill had a pot of coffee available to the farmers to drink while they waited for their daily invoice.

As a company we are obviously very interested in sustainability, and that was a top of interest on the trip as well. Were there any surprises?

One surprising thing we learned while visiting the coffee farm was the restrictions on water usage. There is a creek that runs through the farmland that no one aside from the farm is permitted use. Because the land has been a farm for 120 years and traditionally used the creek for irrigation, they are grandfathered in. Adulteration of this natural resource is so serious that someone is tasked with walking the five miles along the creek every day.

What was your biggest takeaway about coffee origin as it relates to sustainability?

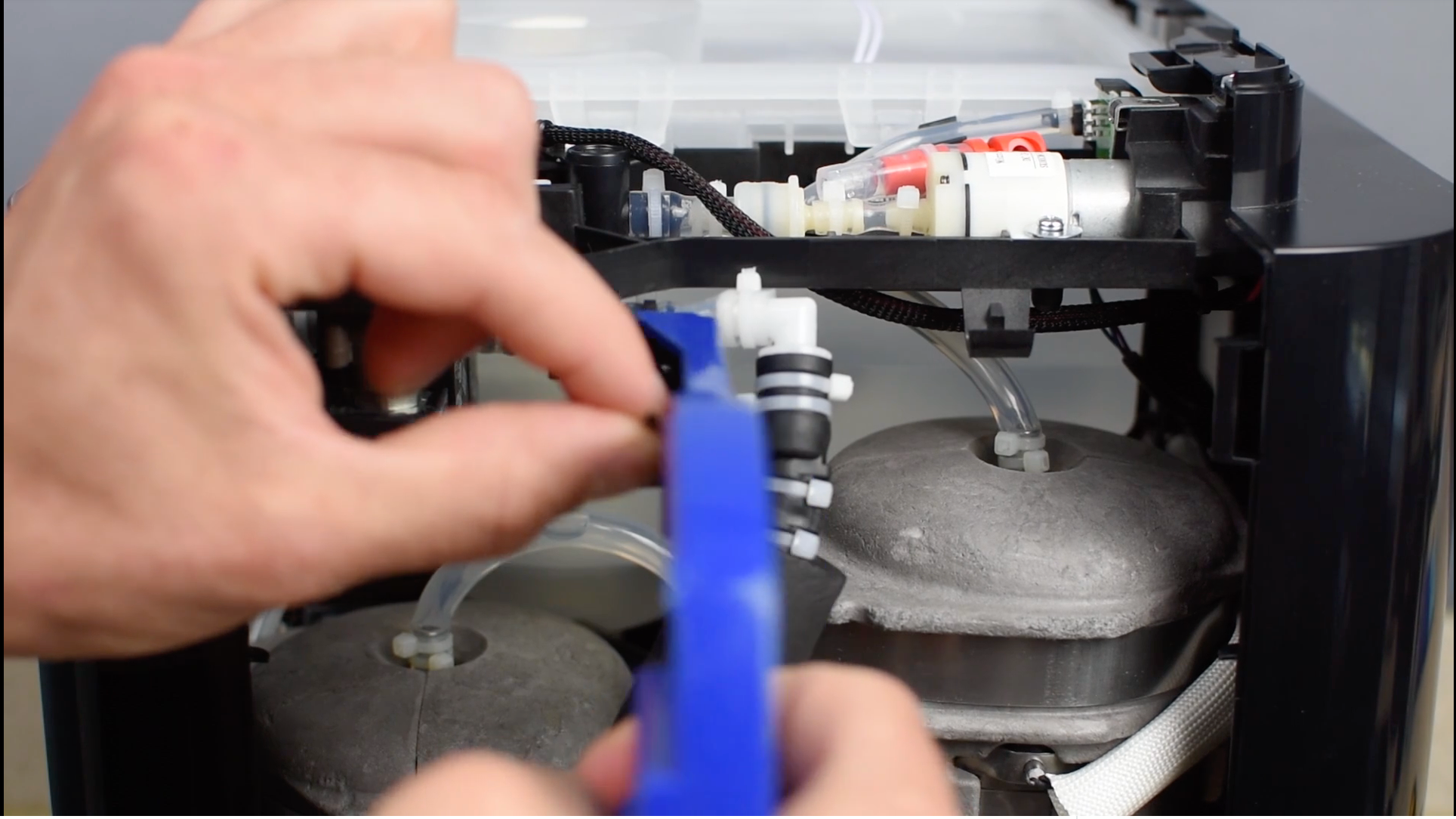

There are many things that can be and are done at origin to impact the sustainability of the product. One example I saw in practice at the mill we visited was the transition from fermentation tanks to a centrifuge for removing the meat of the coffee cherry from the bean. This greatly reduces the water usage at the mill. Just as we are doing research and development here at the roastery to craft delicious brews to fuel the workday, people are working hard to find creative solutions to both quality and sustainability in growing, harvesting, and transporting coffee.